High-Efficiency Continuous Laser Cleaning

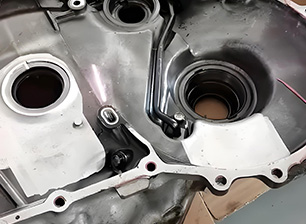

Equipped with a continuous wave laser source, ideal for surface treatment of oil stains, oxide layers, weld cleaning, contaminants, rust spots, and organic coatings.

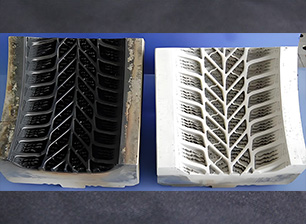

Outstanding Cleaning Performance

Features fast cleaning speed, a maximum scanning width of up to 300 mm, and cleaning thickness up to 100 μm — significantly enhancing operational efficiency.

Advanced Laser Cleaning Principle

Utilizes the high energy and concentration of laser beams to irradiate the workpiece, causing surface contaminants (such as dirt, oxide layers, and rust) to absorb the laser energy and then melt, vaporize, or detach from the substrate through thermal expansion, achieving non-destructive cleaning.

Professional Industry Applications

Widely applied in high-speed railways, large vessels, aerospace, metal processing, and power & telecom industries — meeting diverse cleaning needs across multiple sectors.

Smart Integrated Design

Built with a compact integrated structure, equipped with a dedicated control system and software. Parameters can be flexibly adjusted according to different cleaning requirements, enabling precise and efficient operation.

简体中文

简体中文