Building 3, Hongyuan·Xinzihui, R&D Fifth Road, Songshan Lake Park, Dongguan City, Guangdong Province

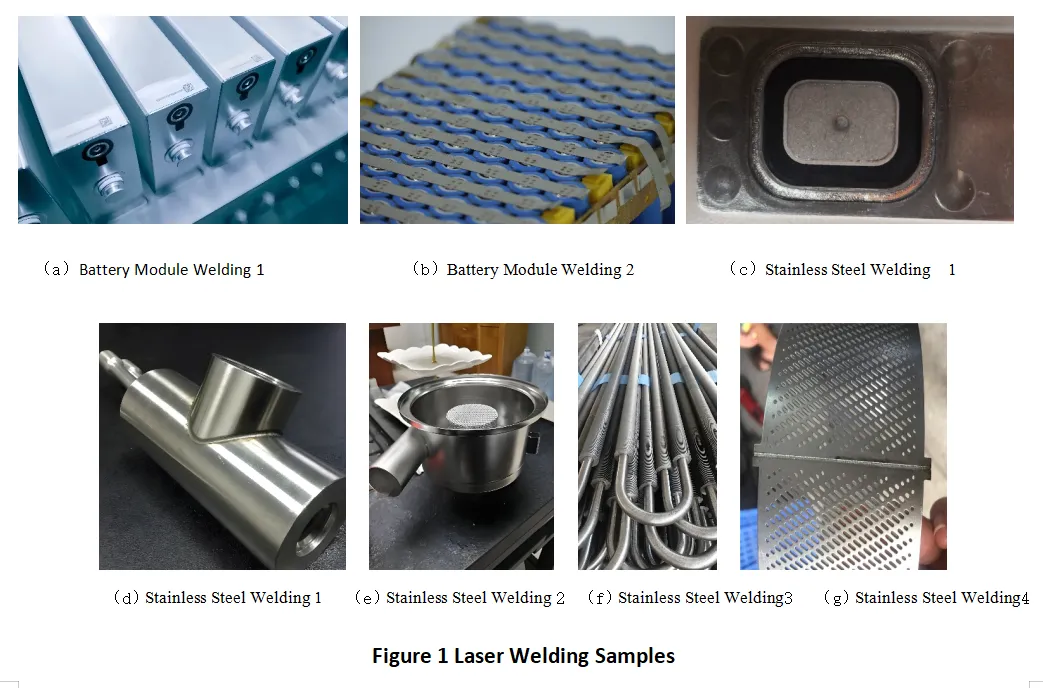

Laser Cleaning and Laser Welding - The Green Revolution in Industry

Text/Zhuofei · Dongguan Yuan Intelligent Creative Technology Co., Ltd.

With the advancement of science and technology and the improvement of global environmental protection requirements, traditional cleaning and welding technologies are facing increasing challenges, especially in terms of environmental protection and production efficiency. In order to meet these growing needs, Dongguan Yuan Intelligent Creative Technology Co., Ltd. (brand: DADO) has launched advanced laser cleaning and laser welding equipment through years of technological accumulation and innovation, providing efficient, environmentally friendly and advanced laser equipment for the global manufacturing industry, helping enterprises to achieve automation upgrades and improve production efficiency.

Dongguan Yuan Intelligent Creative Technology Co., Ltd. (Brand: DADO) is a trading company specializing in the sales, service and technical support of laser cleaning machines and laser welding machines. It is committed to providing efficient, environmentally friendly and advanced laser equipment for the global manufacturing industry, helping enterprises to achieve automation upgrades and improve production efficiency. By introducing the most advanced laser technology, its products are widely used in aerospace, automobile manufacturing, mold manufacturing, ship repair, rail transit, electronics manufacturing, metal processing, home appliance production and other industries, providing customers with professional laser technology solutions to help customers improve production efficiency, reduce operating costs and improve product quality.

Advantages of laser cleaning technology

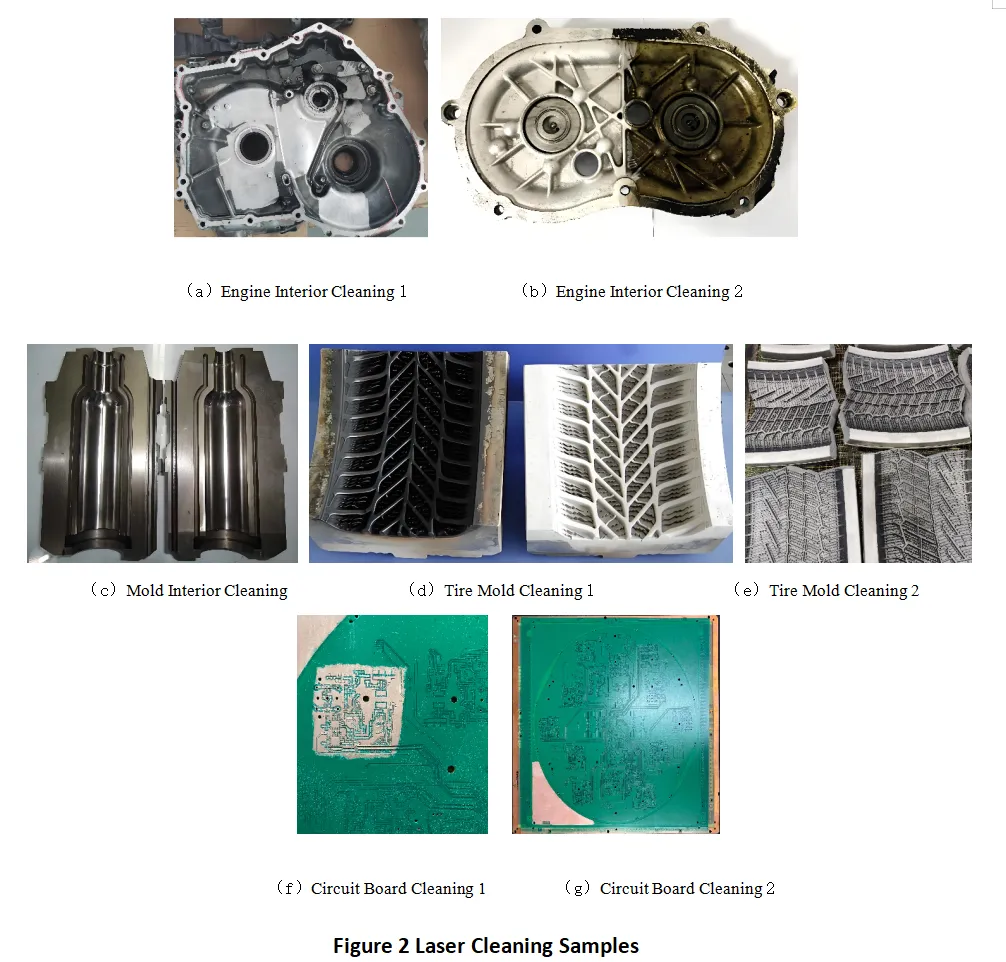

Laser cleaning is a new type of environmentally friendly surface treatment technology. Compared with traditional cleaning methods, laser cleaning has unique advantages.

High-efficiency and energy-savingLaser cleaning uses a laser beam to illuminate the metal surface, which can instantly remove impurities such as oxide layer, rust and oil on the metal surface. The process does not require the use of any chemicals, cleaning liquid, or other external media, which is energy-saving and efficient.

Accurate and high-efficiencyTraditional cleaning methods often easily cause surface wear or pollution, while laser cleaning can specifically and efficiently remove contaminants in designated areas of the metal surface without any damage to the substrate, achieving fine cleaning without contact and damage.

Environmental protection and pollution-freeLaser cleaning process will not produce any harmful gases, wastewater, waste residue and other pollutants, in line with the strict requirements of modern industrial environmental protection. With the increasingly stringent environmental protection requirements, the environmental protection characteristics of laser cleaning undoubtedly make it the preferred cleaning solution for more and more enterprises.

Wide applicabilityLaser cleaning is not only suitable for the removal of rust on metal surfaces, but also for the removal of oil stains, coatings, paints, especially in ship repair, aerospace, rail transit and other industries has great application potential. Whether it is large-scale industrial production, or small-scale repair processing, laser cleaning can provide efficient technical support.

high welding qualityLaser welding uses a high-power laser beam to locally heat the metal, which can be quickly and evenly heated to produce high-quality welded joints with flat and smooth welds. Due to the high energy concentration of the laser, the heat-affected area in the welding process is small, which can effectively avoid the problem of thermal deformation in traditional welding methods.

Welding speedCompared with traditional welding, laser welding speed is very fast, which can greatly improve production efficiency. In industrial production, especially in the welding production of large quantities of parts, the advantages of laser welding are more prominent, which can effectively improve production capacity and save more time.

is suitable for welding complex structuresTraditional welding methods are often difficult to achieve welding of complex structures, and laser welding can overcome these problems well, especially suitable for welding complex structures and thin-walled parts, providing higher flexibility and precision.

does not require filler materialsTraditional welding often requires filler materials, while laser welding can achieve welding without filler materials due to its high energy concentration, further improving processing efficiency and cost control.

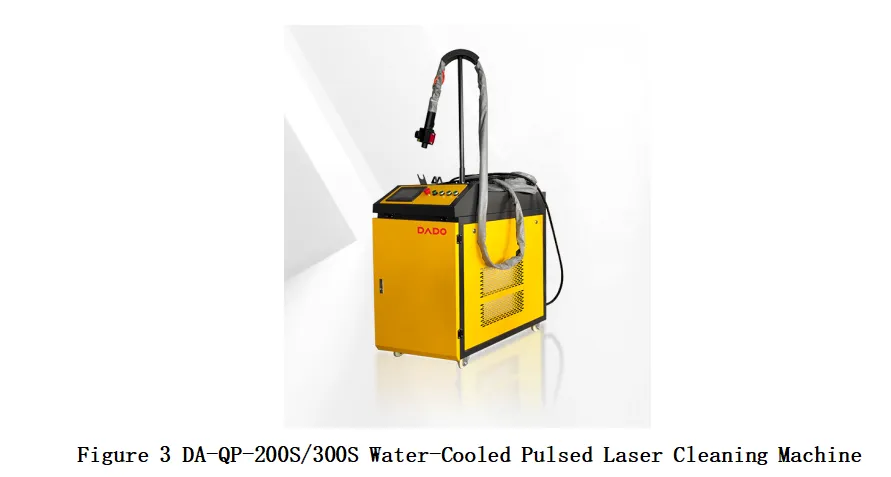

DA-QP-200S/300S water-cooled pulsed laser cleanerDA-QP-200S/300S water-cooled pulsed laser cleaner (Figure 3) uses advanced laser technology and is equipped with an efficient water-cooled system, which can provide a stable working environment and adapt to large-scale industrial production needs. The equipment has the characteristics of high power, high efficiency and low energy consumption, and can quickly remove rust, oil and pollutants on metal surfaces. It is widely used in aerospace, ship repair, mold manufacturing and other industries.

DA-QP-200F/300F Portable Pulsed Laser Cleaning Machine

The DA-QP-200F/300F Portable Pulsed Laser Cleaning Machine (Figure 4), as a compact and lightweight cleaning device, is particularly suitable for applications requiring mobility. Whether in a factory workshop or for on-site maintenance, it efficiently performs metal surface cleaning. It has a wide market demand, especially in fields such as equipment maintenance and component repair.

Conclusion

Dongguan Yuanzhi Creative Technology Co., Ltd. (brand: DADO) is committed to providing customers with efficient, environmentally friendly and advanced laser equipment to help enterprises improve production efficiency, reduce production costs, and promote the green transformation and sustainable development of the industry. Through years of technological accumulation and innovation, it has become a leader in the field of laser cleaning and laser welding equipment. With the continuous progress of science and technology and the continuous expansion of market demand, laser cleaning and laser welding technology will continue to develop, Dongguan Yuan Intelligent Creative Technology Co., Ltd. (brand: DADO) will continue to increase technological research and development efforts, improve product performance, and provide more efficient and environmentally friendly laser equipment for the global manufacturing industry. We believe that in the future industrial production, laser cleaning and laser welding will become more important process means to help all walks of life rapid development.

Next

No.Getlaser technologyapplication solutions!

Our technical team will customize laser process solutions for you

message online

If you have any suggestions or question for us.Please contact us.