Laser Cleaning Process Analysis: Efficient, Safe, and Eco-Friendly

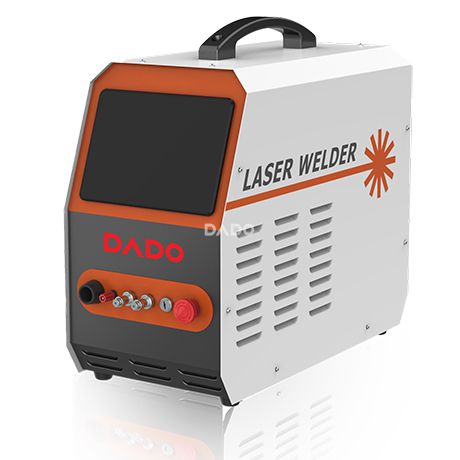

The principle of laser cleaning is to use high-energy short-pulse laser irradiation on a surface, causing contaminants to rapidly heat up, expand, and be removed, while the substrate remains virtually unaffected. This method is especially suitable for applications such as precision parts, molds, and pre-welding treatment. Compared to chemical cleaning, laser cleaning leaves no residue, requires no solvents, and causes no environmental pollution. In contrast to mechanical cleaning, laser cleaning does not damage the surface of the workpiece, avoiding the impact of physical wear. DADO Technology Co., Ltd.'s laser cleaning equipment adopts advanced fiber transmission technology to ensure efficient and stable operation, providing intelligent cleaning solutions for enterprises.

简体中文

简体中文